The company mainly deals in a full range of products including bridge cranes, gantry cranes, electric hoists, etc., and supports one-stop purchasing and franchise cooperation.

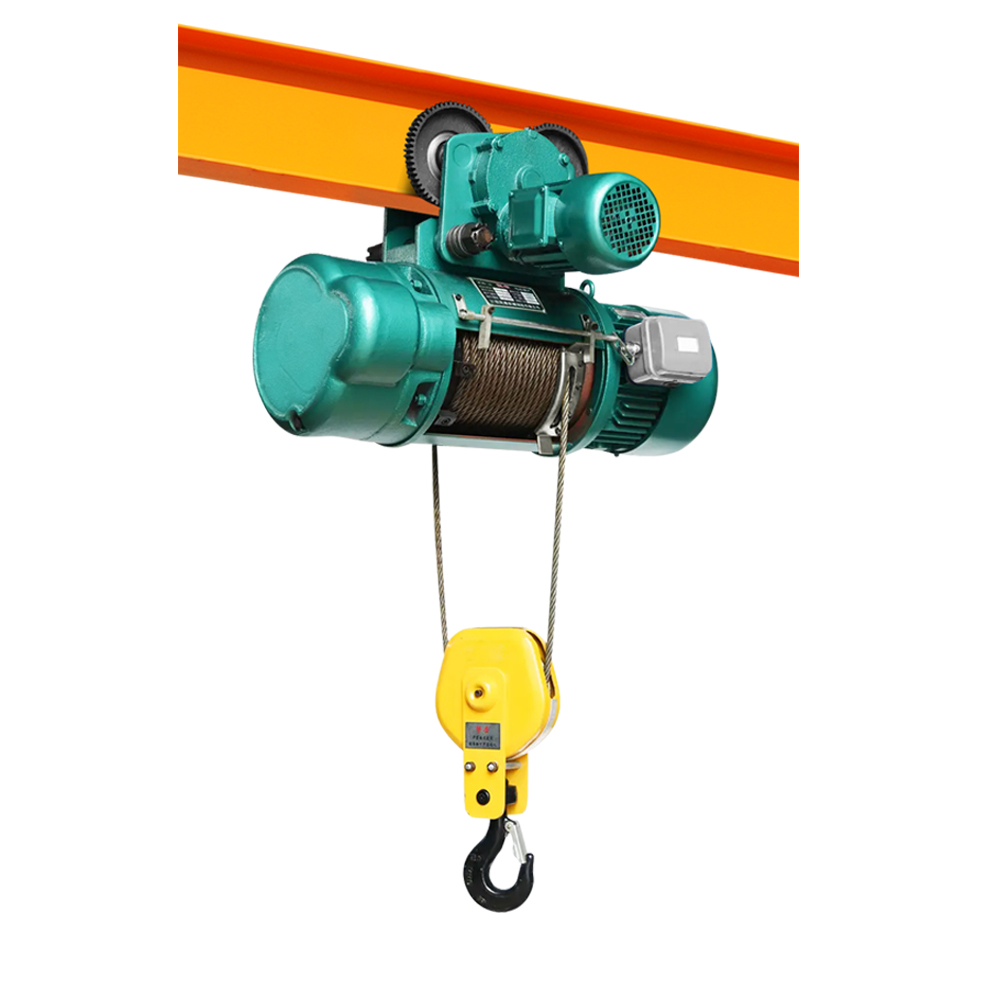

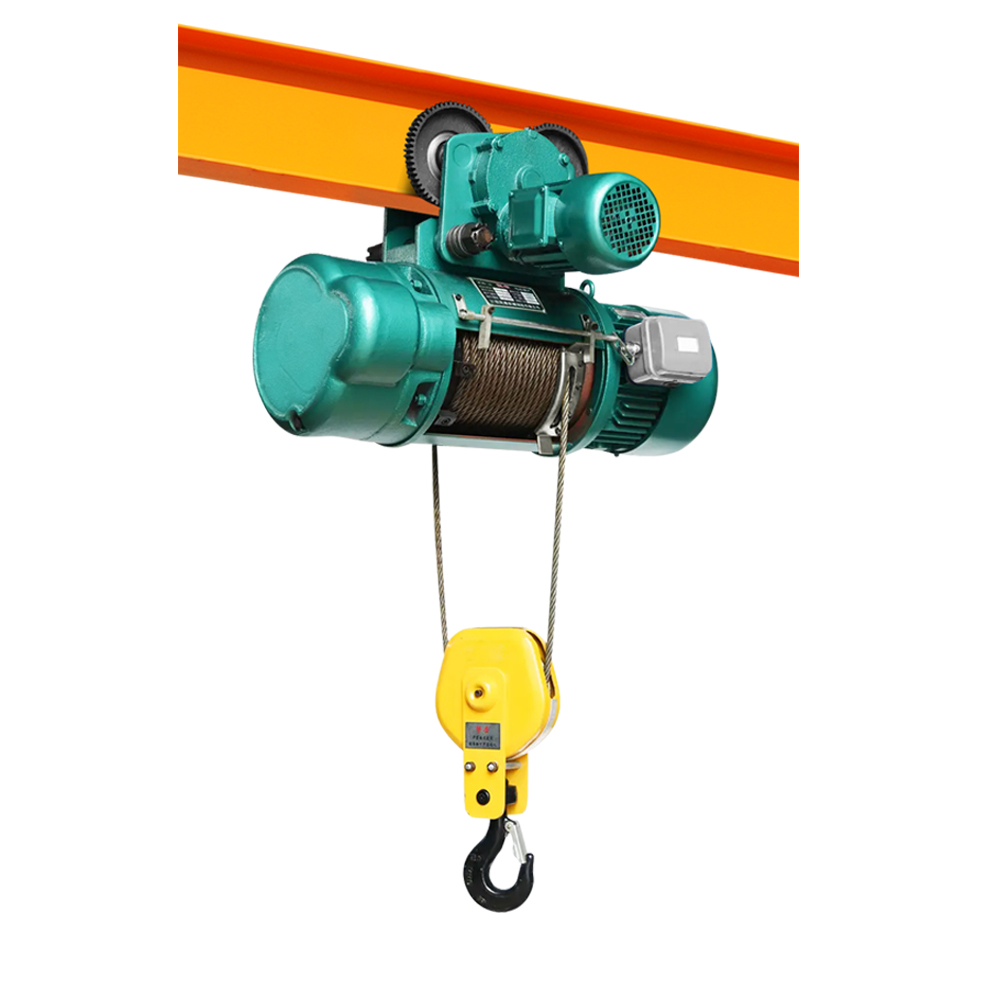

Industrial-grade hoist: the core of precise and efficient intelligent handling

The world's trusted hoisting power source|the creator of safety standards

Product definition

The hoist (including electric hoist) is a heavy object vertical lifting equipment with motor drive as the core, which realizes the precise retraction and release of wire rope/chain through the gear transmission system. As the core component of independent slings or bridge/gantry cranes, our products cover the full range from micro (0.25 tons) to heavy (100 tons), meeting the stringent requirements of precise positioning, frequent start and stop, high-risk environment, etc., and a single machine can build a complete lifting system.

Disruptive product advantages

⓵ Extreme reliability and lifespan

- Military-grade transmission system: carburized gears with hardened tooth surfaces (lifespan ≥ 100,000 hours) + hot-forged alloy hooks (4 times safety factor)

- Three-proof reinforced design: insulation grade H (180℃ temperature resistance) | IP65 protection (anti-dust spray) | F-grade anti-corrosion coating (salt spray test 1000h)

- Overload protection: mechanical friction clutch + electronic load limit double insurance (error <±3%)

⓶ Intelligent control revolution

- Precise micro-motion mode: 0.8m/min micro-speed positioning (essential for precision assembly scenarios)

- Ergonomic handle: emergency stop + 0-10m/min stepless speed change + OLED screen display (real-time load/power)

⓷ Energy efficiency benchmark

- Permanent magnet synchronous motor saves 30% energy (compared to traditional asynchronous motor)

- Energy feedback technology: automatic energy storage during descending power generation (CE certification)

- Maintenance-free design: self-lubricating gearbox + sealed bearing (5 years of oil-free)

Full-scenario application coverage

| Field | Typical scenarios | Customized solution highlights |

| Automobile manufacturing | Engine hoisting/production line transportation | Low-headroom two-speed hoist (height <1m) |

| Port logistics | Container repair/cargo ship material supply | Anti-sway frequency conversion control + remote control |

| Energy engineering | Wind turbine tower assembly/power station maintenance | 80-ton large capacity + wind-resistant locking device |

| Intelligent manufacturing | Robot collaboration/precision instrument handling | Servo control ±0.5mm positioning accuracy |

| Special environment | Explosion-proof warehouse/cold storage (-40℃) | Ex d IIC T4 explosion-proof certification |

Global reasons for choosing us

✓ Vertical field technology dominance

- Member unit of China Hoisting Machinery Standardization Committee

- 30% export share ranks first in the industry

✓ Deep customization capabilities

- Fast delivery: 72-hour delivery of conventional models (inventory > 2,000 units)

- Strong adaptation: support non-standard customization (voltage 440V/60Hz | tropical mildew proof | nuclear grade earthquake resistance)

✓ Zero time difference global service

- 5-year warranty commitment for key components (motor/gearbox)

- Accident response mechanism: issue a fault analysis report within 48 hours, and provide online guidance

✓ Real cost reduction

▶ Case of a shipyard: After replacing old equipment, the failure rate dropped by 90%, and the annual maintenance cost was reduced by ¥380,000

▶ Case of an airport: The permanent magnetic hoist group solution reduced energy consumption by 41% (LEED certification bonus points)

Start smart lifting upgrades immediately, contact our service team

Leave a Reply

Your email address will not be published. Required fields are marked *